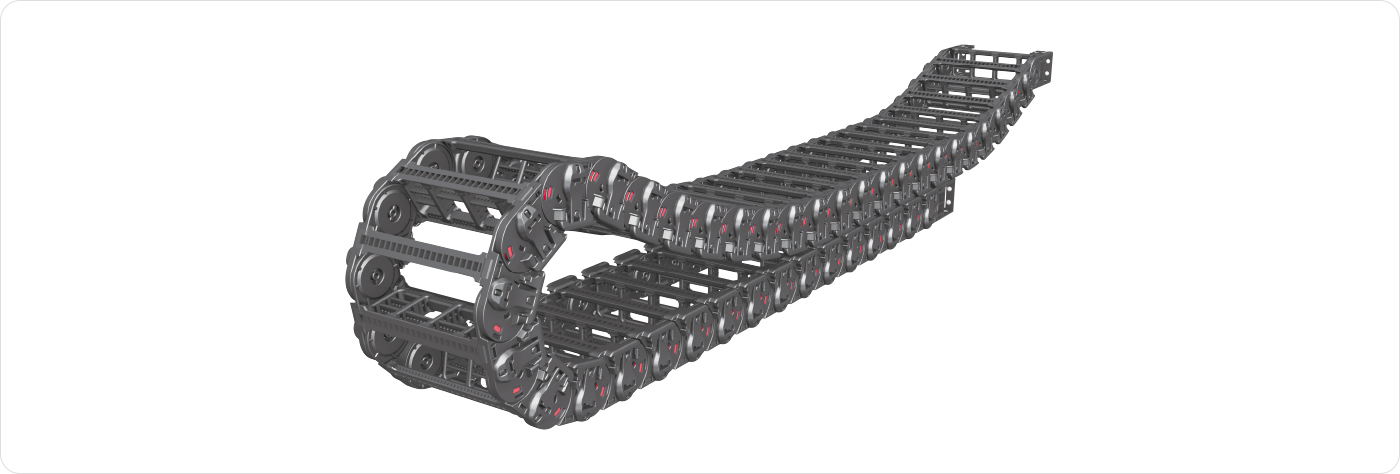

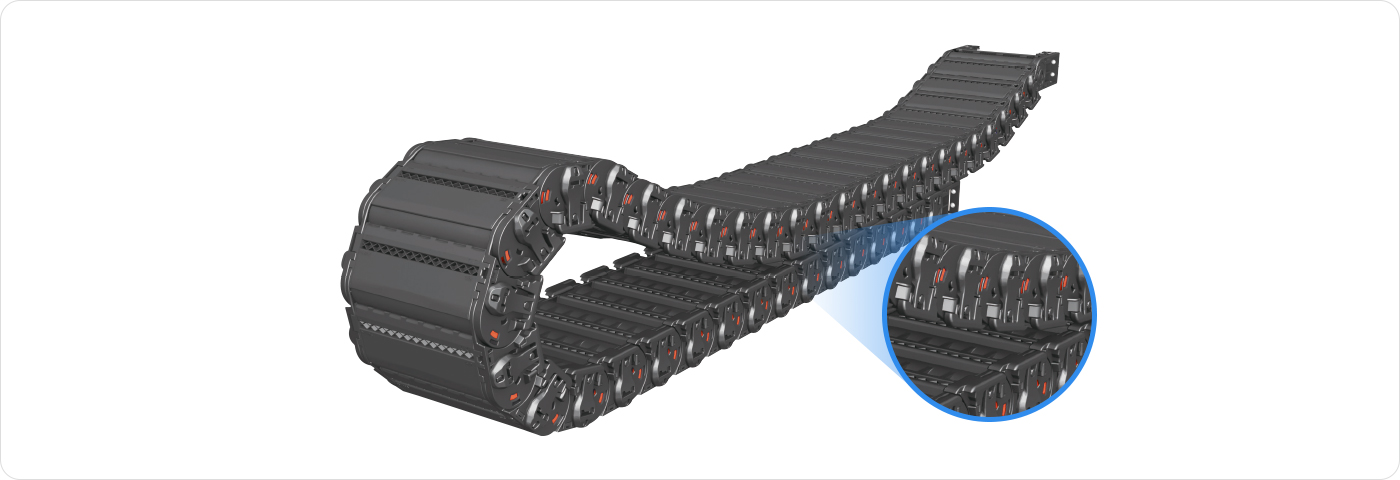

CHARACTERISTIC AND MERIT OF SHIFT CHAIN

Shift chain is the next generation cable of chain developed to protect the inner cables and hoses applied to equipment and machinery of overall industries.

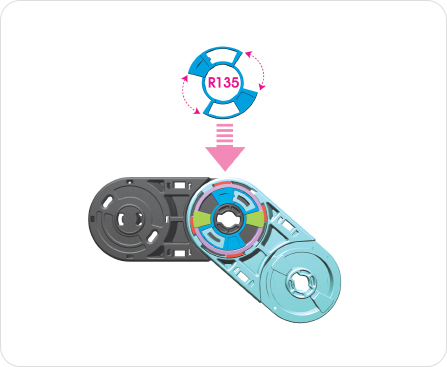

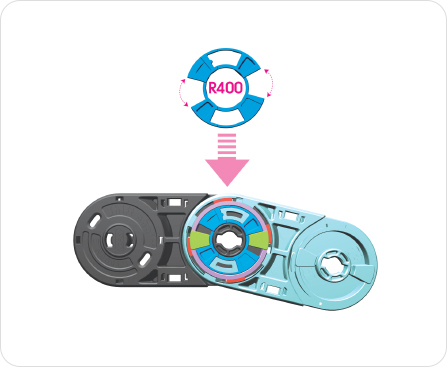

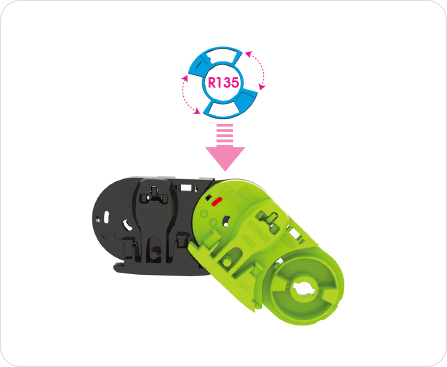

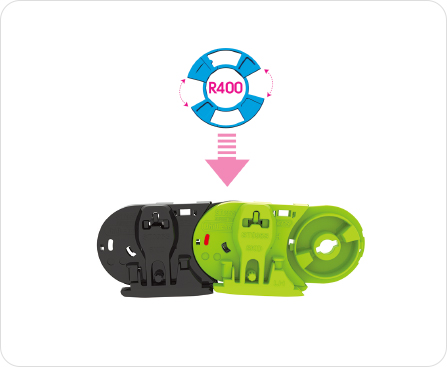

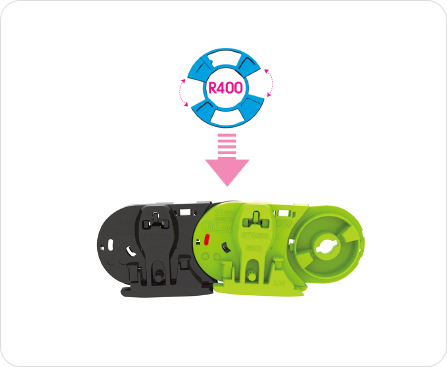

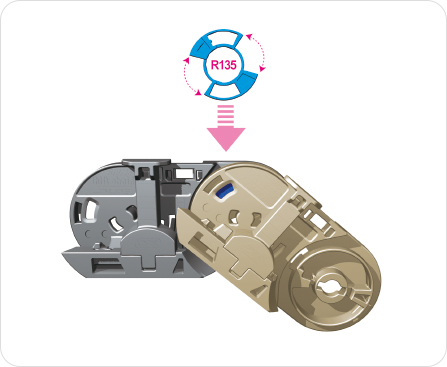

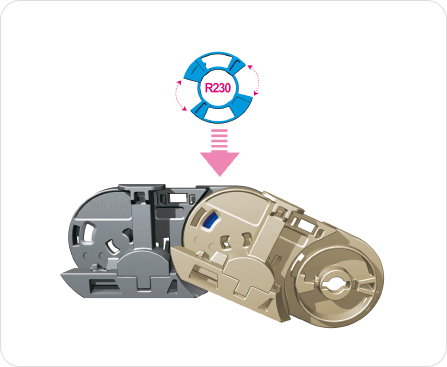

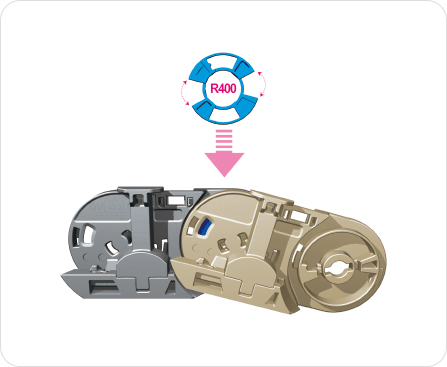

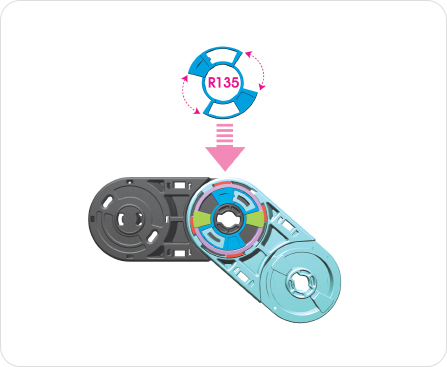

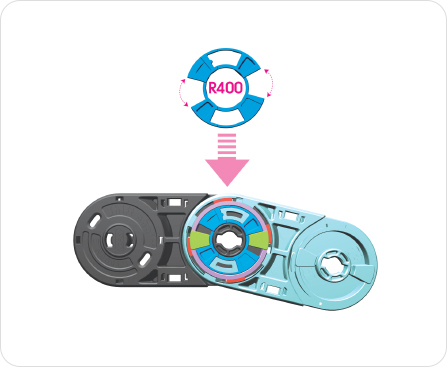

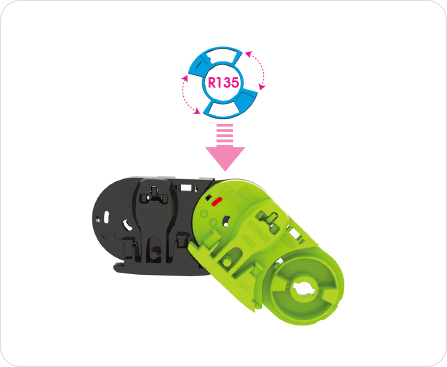

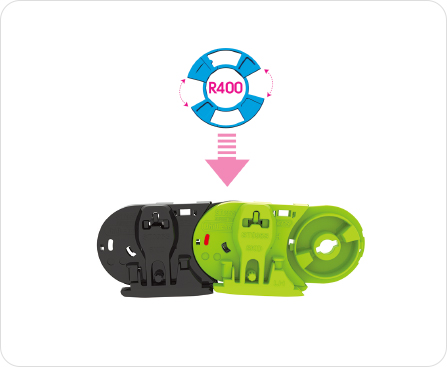

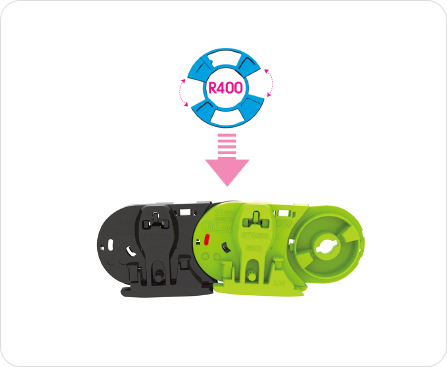

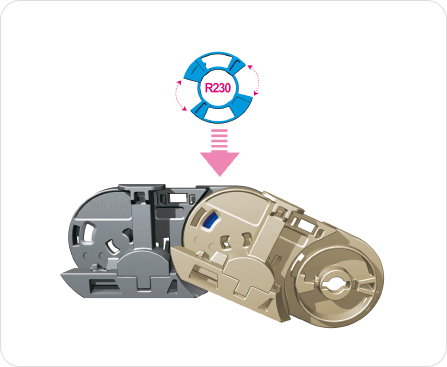

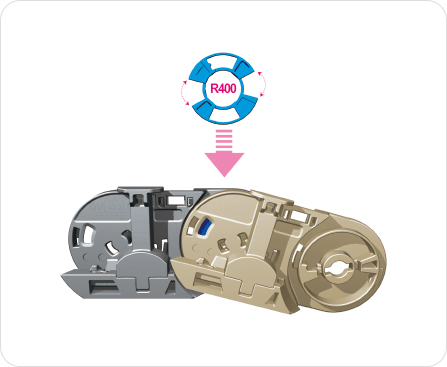

Shift Chain, with the unique structure, is a new concept that the value of Bending Radius is decided by the independent Bending Radius unit inserted.

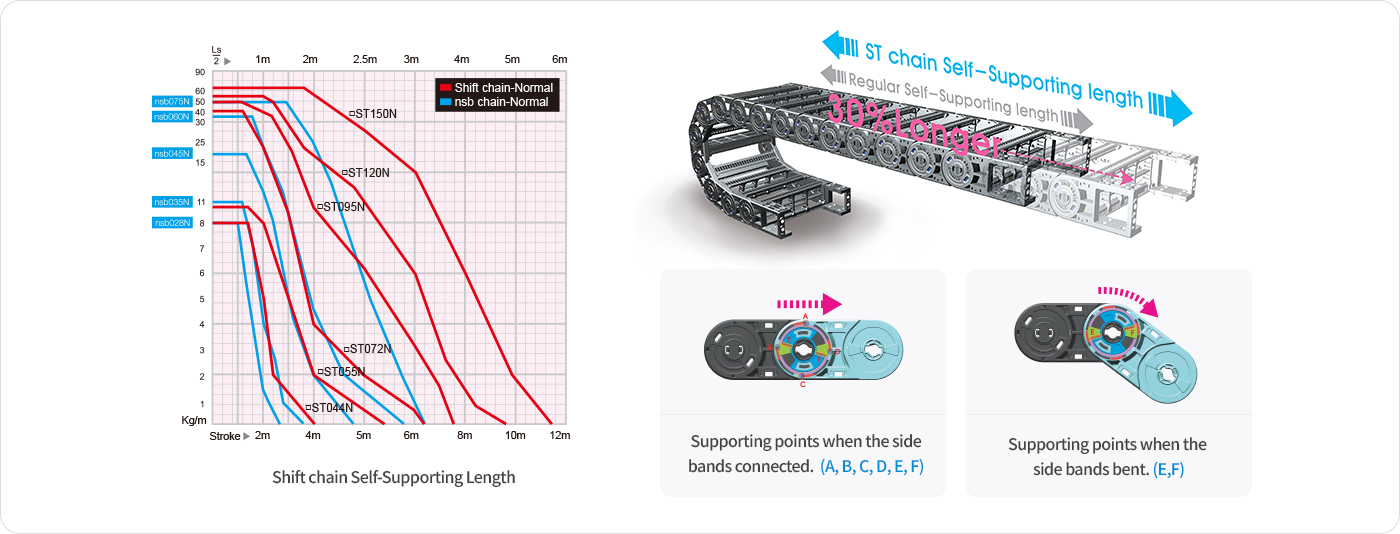

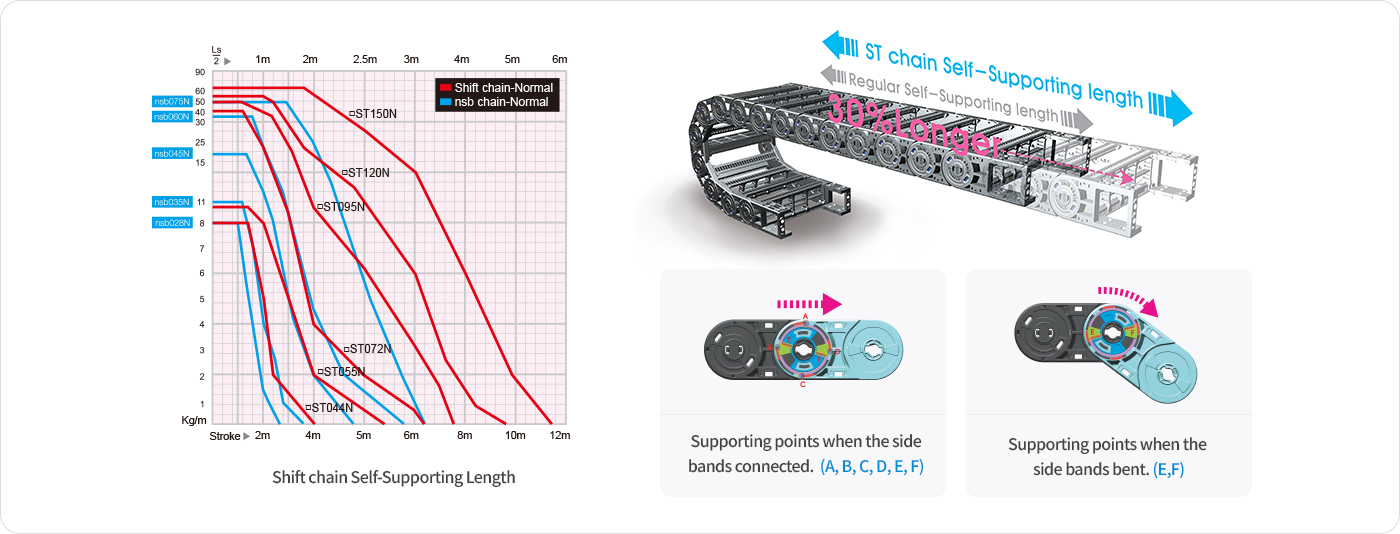

As BR unit(Bending radius unit) has 6 points of supporting area when inserted into side band, its durability and self-supporting level are 30% longer than previous models and other models of CPS.

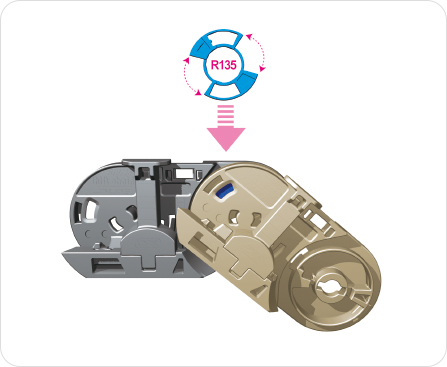

Shift Chain Normal Type

In R135 BR connection

In R230 BR connection

In R400 BR connection

-

ST 044N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

- Applications

GantryRobot, atherMachine, WeldingMachine, PrintingMachine, Robot

-

ST 055N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

GantryRobot, MatherMachine, WeldingMachine, PrintingMachine, Also can be used for workplaces where cable chain ssuch as robot carriage are applied

-

ST 072N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

F : Multi-faceted end bracket

G : Guide Janelle End Bracket (Unity Systems)

V : Vertical Guide Janelle End Bracket (Unity Systems)

T : Tie Wrap

S : System Tie Wrap

- Applications

Gantry Robot, Mather Machine, Textile Machine, Welding Machine, Feeder Unit, Assembly Loader, Woodwork Machine, Fabric Machine

-

ST 095N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

F : Multi-faceted end bracket

G : Guide Janelle End Bracket (Unity Systems)

V : Vertical Guide Janelle End Bracket (Unity Systems)

T : Tie Wrap

S : System Tie Wrap

- Applications

Gantry Robot, Mather Machine, Welding Machine, Printing Machine, Alsocanbe used for work places where cable chain ssuch as robot carriage are applied

-

ST 120N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Gantry Robot, Mather Machine, Welding Machine, Printing Machine, Alsocanbe used for work places where cable chain ssuch as robot carriage are applied

-

ST 150N

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Gantry Robot, Mather Machine, Welding Machine, Printing Machine, Alsocanbe used for work places where cable chain ssuch as robot carriage are applied

-

ST 044E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Applies to welding lines, painting lines, gentry robots, machine tools, welding machines, robot carriages, etc.that require protection of cables from industrial sites and external hazards

-

ST 055E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Applies to welding lines, painting lines, gentry robots, machine tools, welding machines, robot carriages, etc.that require protection of cables from industrial sites and external hazards

-

ST 072E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 6.0m

Vertical curve below = max 100m

Side Mounted, Unsupported = max 2.5m

- Applications

Applies to welding lines, painting lines, etc.that require protection of cables from industrial sites and external risk factors. Can be used in work places where cable chains are applied that require protection from external risk factors such as gentrification robots, machine tools, welding machines, and robot carriage.

-

ST 095E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Applies to welding lines, painting lines, gentry robots, machine tools, welding machines, robot carriages, etc.that require protection of cables from industrial sites and external hazards

-

ST 120E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Applies to welding lines, painting lines, gentry robots, machine tools, welding machines, robot carriages, etc.that require protection of cables from industrial sites and external hazards

-

ST 150E

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Low Noise & Low Mote

-

- Speed

6㎧

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Other installation Length

Vertical curve above = max 2.0 ~ 7.0m

Vertical curve below = max 40 ~ 150m

Side Mounted, Unsupported = max 1.0 ~ 4.0m

- Applications

Applies to welding lines, painting lines, gentry robots, machine tools, welding machines, robot carriages, etc.that require protection of cables from industrial sites and external hazards

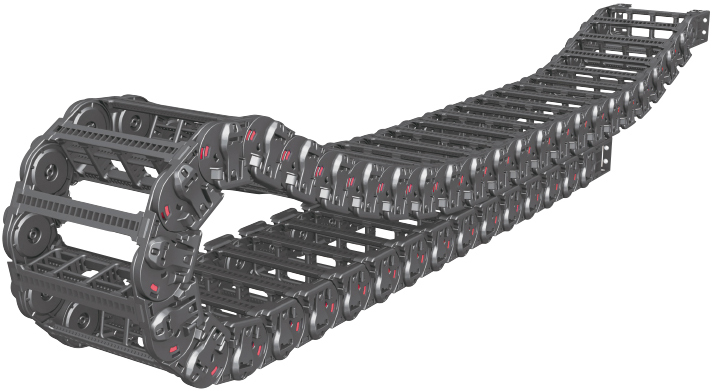

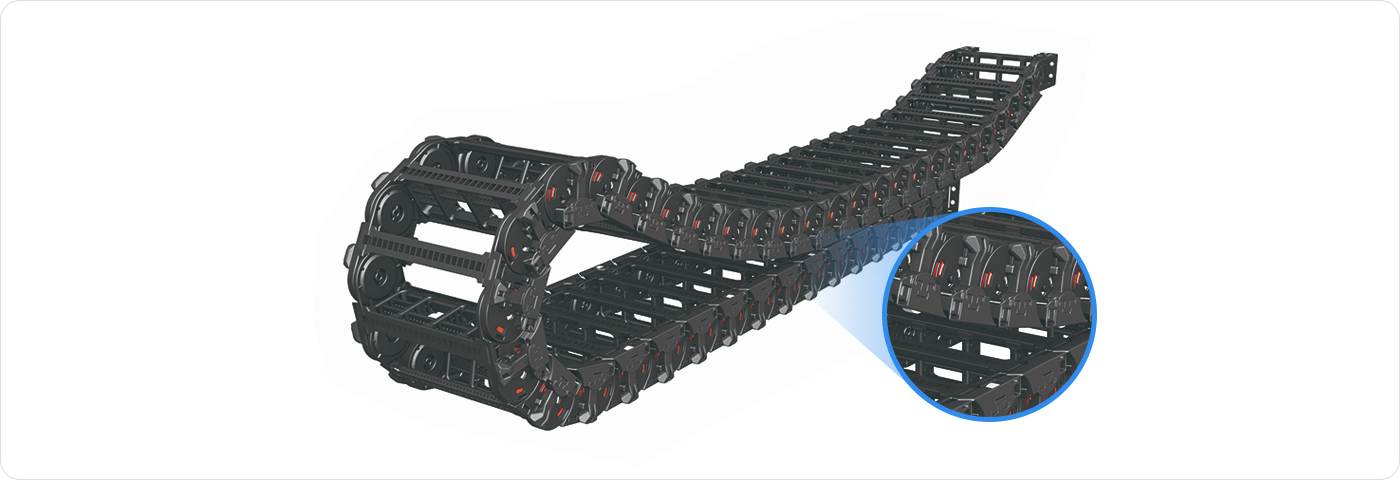

CHARACTERISTIC AND MERIT OF SHIFT CHAIN

Shift chain is the next generation cable of chain developed to protect the inner cables and hoses applied to equipment and machinery of overall industries.

Shift Chain, with the unique structure, is a new concept that the value of Bending Radius is decided by the independent Bending Radius unit inserted.

ST - S : Skid type

- 1

To minimize noise and make stable driving of chain, applies a SKID to the friction surface and those are touched each other smoothly.

- 2

Improved structure of Side Band could make stronger durability and develop most suitable parts to protect cable damage.

- 3

Durability has been enhanced by improving the structure of the sideband, and it has been developed to prevent cable damage by optimizing the design of each part.

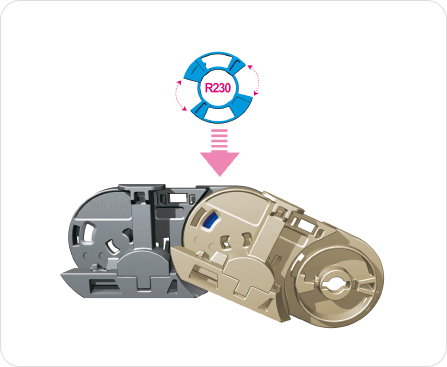

Descriptions (Shift Chain Skid Type)

In R135 BR connection

In R230 BR connection

In R400 BR connection

-

ST 044S

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.3 ~ 0.4μ

- Applications

Gantry Robots, Robot Carriages, Automatic Welding Lines, Gantry Cranes, Gantry loder etc.

Affer using skid for a long time, it can be replaced without extra components.

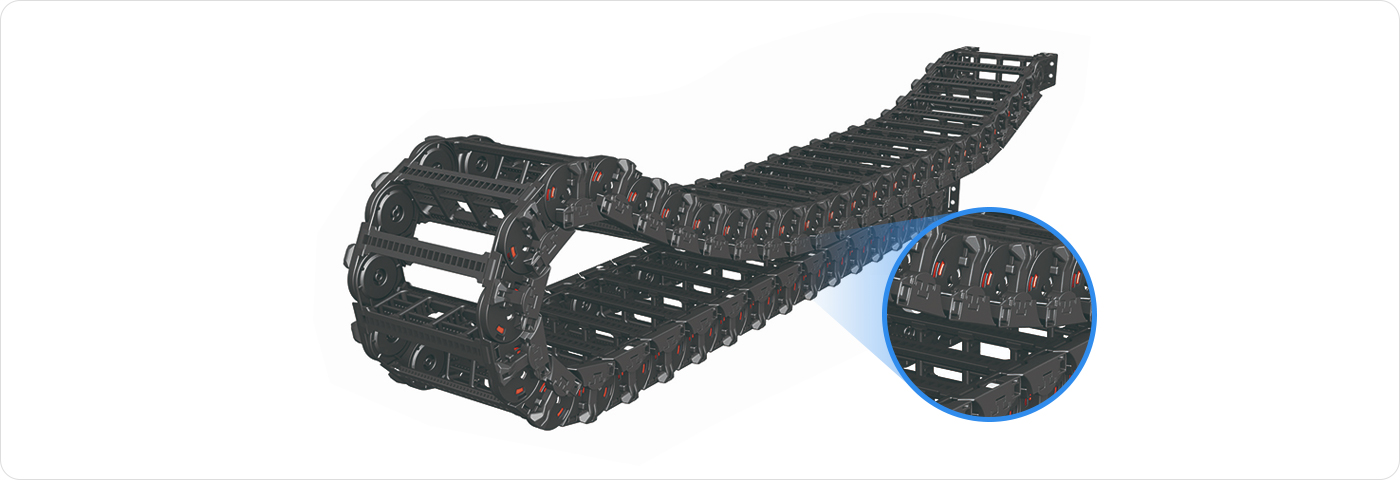

CHARACTERISTIC AND MERIT OF SHIFT CHAIN

Shift chain is the next generation cable of chain developed to protect the inner cables and hoses applied to equipment and machinery of overall industries.

Shift Chain, with the unique structure, is a new concept that the value of Bending Radius is decided by the independent Bending Radius unit inserted.

ST - ES : ENCLOSED SKID TYPE

- 1

To protect cables perfectly from outside substance, enclosed frame is applied to the ST-S Type for long distance application.

- 2

This chain can be used in workplace with poor surroundings such as dusts, paints and machining chip etc.

- 3

Application: cutting, welding, panting line etc.

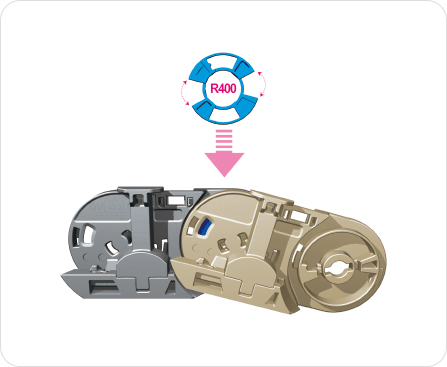

Descriptions (Shift Enclosed Skid Type)

In R135 BR connection

In R230 BR connection

In R400 BR connection

-

ST 044ES

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.3 ~ 0.4μ

- Applications

Gantry Robots, Robot Carriages, Automatic Welding Lines, Gantry Cranes, Gantry loder, etc. Gantry robots, Robot carriages, Automatic welding Gantry crane, Gantry loader etc.

Shift Chain ES-Type can be found on car manufacturer's welding line, where excess material can damage your inserted cables.

-

ST 072ES

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.3 ~ 0.4μ

- Applications

Gantry Robots, Robot Carriages, Automatic Welding Lines, Gantry Cranes, Gantry loder, etc. Gantry robots, Robot carriages, Automatic welding Gantry crane, Gantry loader etc.

Shift Chain ES-Type can be found on car manufacturer's welding line, where excess material can damage your inserted cables.

-

ST 095ES

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.3 ~ 0.4μ

- Applications

Gantry Robots, Robot Carriages, Automatic Welding Lines, Gantry Cranes, Gantry loder, etc. Gantry robots, Robot carriages, Automatic welding Gantry crane, Gantry loader etc.

Shift Chain ES-Type can be found on car manufacturer's welding line, where excess material can damage your inserted cables.

-

ST 120ES

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.3 ~ 0.4μ

- Applications

Gantry Robots, Robot Carriages, Automatic Welding Lines, Gantry Cranes, Gantry loder, etc. Gantry robots, Robot carriages, Automatic welding Gantry crane, Gantry loader etc.

Shift Chain ES-Type can be found on car manufacturer's welding line, where excess material can damage your inserted cables.

CHARACTERISTIC AND MERIT OF SHIFT CHAIN

Shift chain is the next generation cable of chain developed to protect the inner cables and hoses applied to equipment and machinery of overall industries.

Shift Chain, with the unique structure, is a new concept that the value of Bending Radius is decided by the independent Bending Radius unit inserted.

ST - RS : ROLLER SKID TYPE

- 1

To minimize frictional force resulted in disturbing from a SKID, applies a Roller to the friction surface and those are touched each other smoothly.

※ The coefficient of friction : 0.02~0.07u (Normal Cable chain:0.3~0.04u)

- 2

It is suitable for the long distance equipment with heavy weight of cable.(more then 50m)

- 3

The application of the roller has a high load on the cable and issuitable for long-distance driving facilities.(50m or more)

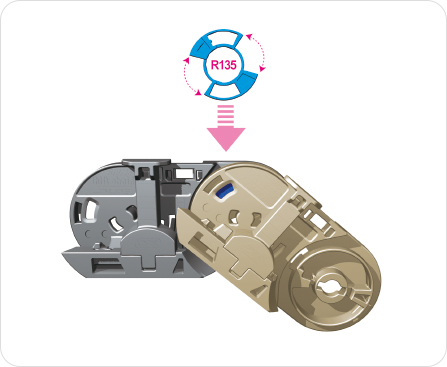

Descriptions (Shift Roller Skid Type)

In R135 BR connection

In R230 BR connection

In R400 BR connection

-

ST 044RS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

With a frictio co-efficiency of 0.02~0.07μ due to the patented roller skid design, the Shift Chain is quieter and faster than ever. Non friction also means no dust for those applications where a clean work environment is a priority.

-

ST 072RS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

With a frictio co-efficiency of 0.02~0.07μ due to the patented roller skid design, the Shift Chain is quieter and faster than ever. Non friction also means no dust for those applications where a clean work environment is a priority.

-

ST 095RS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

With a frictio co-efficiency of 0.02~0.07μ due to the patented roller skid design, the Shift Chain is quieter and faster than ever. Non friction also means no dust for those applications where a clean work environment is a priority.

-

ST 120RS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

With a frictio co-efficiency of 0.02~0.07μ due to the patented roller skid design, the Shift Chain is quieter and faster than ever. Non friction also means no dust for those applications where a clean work environment is a priority.

CHARACTERISTIC AND MERIT OF SHIFT CHAIN

Shift chain is the next generation cable of chain developed to protect the inner cables and hoses applied to equipment and machinery of overall industries.

Shift Chain, with the unique structure, is a new concept that the value of Bending Radius is decided by the independent Bending Radius unit inserted.

ST - ERS : ENCLOSED ROLLER SKID TYPE

- 1

As applying the enclosed frame to ST-RS Type, the cable can be also protected from the any substance perfectly same as ST-RS Type, furthermore, it can be used in more wider place.

- 2

It is suitable for the long distance equipment with heavy weight of cable.(more then 50m)

- 3

This chain can be used in workplace with poor surroundings such as dusts, paints and machining chip etc.

Descriptions (Shift Roller Skid Type)

In R135 BR connection

In R230 BR connection

In R400 BR connection

-

ST 044ERS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

Shift Chain ERS-Type can be found on car manufacturer’s welding line, where excess material cna damage your inserted cables.

-

ST 072ERS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

Shift Chain ERS-Type can be found on car manufacturer’s welding line, where excess material cna damage your inserted cables.

-

ST 095ERS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

Shift Chain ERS-Type can be found on car manufacturer’s welding line, where excess material cna damage your inserted cables.

-

ST 120ERS

- Chain material

CPS-amide with glass fiber reinforced UL94-HB

- Acceleration

10㎨

- Temperature

-30℃ ~ +130℃

- Coefficient of Friction

0.02 ~ 0.07μ

Regular Cable Chain : 0.3 ~ 0.4μ

- Applications

Shift Chain ERS-Type can be found on car manufacturer’s welding line, where excess material cna damage your inserted cables.